Table of Content [ Show ]

If you take a closer look at the electric outlets of older homes in the United States, you would likely see some that have two prongs while others have three. This is because the requirement for three-pronged outlets in homes in the country only began in the 1960s. However, it's important to note that the adoption and enforcement of this requirement varied by region and jurisdiction. The third prong on these outlets serves as a grounding connection. This article will help you understand what is ground in electricity and how it works.

What is Ground in Electricity

Electrical grounding involves connecting electrical circuits and equipment to the earth or a conductive body to establish a reference point for voltage levels and provide a safe path for fault currents. Its primary purpose is to protect against electric shock, fires, and equipment damage.

The idea behind grounding is to keep all conductive parts of an electrical system at the same voltage, reducing the risk of electric shocks and ensuring equipment runs safely. Grounding systems include components like ground electrodes, conductors, rods, and electrodes, which work together to direct electrical currents safely into the ground if something goes wrong. Understanding grounding is crucial for addressing what is a ground fault, which occurs when an electrical current takes an unintended path to the ground, potentially causing hazards or damage.

Parts of a Grounding System

-

Grounding Electrode - a buried metal rod or plate near the home that connects the grounding wire and earth.

-

Grounding Conductor- a copper or aluminum wire connecting the electrical system to the grounding electrode.

-

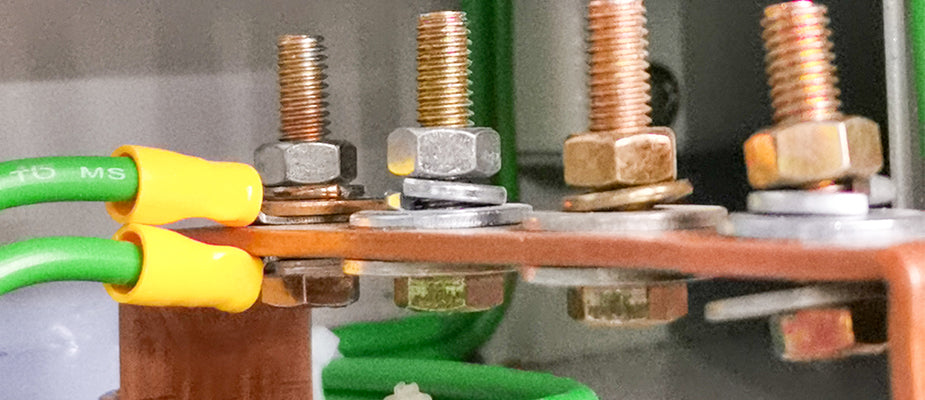

Grounding Bus Bar - a metal bar inside the main electrical panel that serves as the central point for grounding connections.

- Grounding Terminal - outlet or device point where the grounding conductor connects to provide a path for fault currents.

Importance of Electrical Grounding

As mentioned, electrical grounding is essential for protecting people and property from electrical hazards. Its main purpose is to prevent electric shocks and reduce the risk of fires and equipment damage by providing a safe path for fault currents. Fault current is the flow of electrical current that occurs when an unintended or abnormal connection happens in an electrical system, such as due to a short circuit, ground fault, or other malfunction. So, what does a ground wire do? A ground wire provides that safe path for fault currents, ensuring they flow safely into the earth and preventing potential harm or damage.

Proper grounding safeguards electrical equipment from damage caused by voltage surges, and lightning strikes. It provides a safe path for excess electrical energy to dissipate into the ground. For example, when voltage surges occur from lightning strikes or power grid fluctuations, grounding serves as a low-resistance conduit or channel for this excess energy. This prevents it from damaging electrical appliances and causing fires.

Overall, grounding contributes to the stability and reliability of electrical systems by maintaining consistent voltage levels and minimizing fluctuations. This is essential for ensuring the smooth and uninterrupted operation of electrical equipment and preventing disruptions in power supply. An added benefit is that it sustains the durability and lifespan of major appliances and electrical installations, consequently minimizing the need for costly repairs. So, what is ground in electricity? In electrical terms, ground refers to a common reference point, typically the Earth, that serves as the safe path for excess or fault currents to flow, ensuring safety and stability in the system.

Types of Electrical Grounding

There are different types of grounding systems because of various factors such as the age of the home, local building codes, and the specific electrical requirements of the installation.

System Grounding

System grounding involves connecting one of the conductors of an electrical system to the ground. Common types of system grounding include solid grounding, resistance grounding, and reactance grounding, each serving specific purposes in different applications. Solid grounding directly connects the neutral point to the earth, while resistance grounding adds a resistor to limit fault current magnitude. Reactance grounding uses an inductor or reactor to limit the rate of rise of fault currents, particularly in high-voltage systems or where stability is crucial.

Equipment Grounding

Equipment grounding focuses on connecting non-current-carrying metal parts of electrical equipment to the ground. For instance, the metal casing of the refrigerator is considered a non-current-carrying metal part of electrical equipment. To ensure safety, the refrigerator is built with an equipment grounding system which typically involves a three-pronged power cord.

Grounding Electrode Systems

Grounding electrode systems are comprised of various electrodes buried in the earth to provide a low-resistance path for fault currents. These electrodes enhance soil conductivity and facilitate effective grounding in diverse environments.

Grounding in Different Applications

In residential settings, grounding is essential for protecting occupants and ensuring the safe operation of electrical systems. Practices include grounding outlets, surge protectors, and electrical panels to minimize the risk of electrical hazards. Some of Nature's Generator products are equipped with grounding terminals. This includes whole-home solar generator systems such as the Nature’s Generator Powerhouse. It features a grounding terminal to ensure safe and effective operation, allowing users to connect them to grounding systems for added protection against electrical hazards. You can send us a message to know more about this.

Commercial establishments require robust grounding systems to safeguard personnel, equipment, and infrastructure. Common solutions include grounding grids, bonding conductors, and surge suppression devices to maintain operational safety and reliability.

In industrial environments, grounding is critical for ensuring the safety and integrity of electrical systems. Grounding transformers, equipotential bonding, and lightning protection systems are integral components of industrial grounding solutions.

What is ground in electricity? In the context of electricity, "ground" refers to a reference point in an electrical circuit that is considered to have zero voltage. It is used as a safety mechanism to direct electrical current safely into the earth, reducing the risk of electric shock, fire, or equipment damage. Grounding ensures that any stray or fault currents in electrical systems are safely diverted away from sensitive equipment and individuals, helping to protect both personnel and infrastructure in industrial settings.

Lastly, telecommunications systems rely on grounding for signal integrity, equipment protection, and personnel safety. Grounding busbars, surge arrestors, and bonding conductors ensure effective grounding in telecommunications facilities.

Design and Installation of Grounding Systems

To determine the most suitable grounding system for a specific application, field workers or electricians typically assess the site conditions, and soil resistivity, among other factors such as fault current levels and equipment sensitivity. All of these plus a proper installation must be considered to ensure optimal performance.

An expert or an electrician will typically do the following steps in installing a grounding system:

|

Check soil type and potential hazards. |

|

Choose suitable grounding rods, conductors, and connectors. |

|

Sketch where the equipment is and how you'll connect it to the ground. |

|

Dig holes for ground rods or electrodes. Insert rods securely into the ground |

|

Attach grounding conductors to rods and run them to equipment. |

|

Connect metal structures to the grounding system. |

|

Use a ground resistance tester to ensure proper grounding. |

|

Keep records of the installation and test results. |

Additionally, homeowners can check if the installation meets local safety regulations as well as inspect the system periodically for damage or corrosion.

Testing and Maintenance of Grounding Systems

Regular testing of grounding systems is essential to verify their integrity and performance. Ground resistance measurements and continuity tests are common methods used to assess grounding effectiveness and identify potential issues.

Ongoing maintenance such as inspections, cleaning of electrodes, and repairs to damaged components, are necessary to extend the system lifespan and reduce the risk of malfunctions.

Conclusion

Electrical grounding is a fundamental aspect of electrical engineering that is essential for ensuring the safety, reliability, and efficiency of electrical systems. By understanding the principles, applications, and significance of electrical grounding, homeowners can obtain systems that meet the highest standards of safety and performance. So, what is ground in electricity? Grounding refers to the process of connecting an electrical system or device to the earth, providing a common return path for electric current and ensuring that excess charge or fault currents can safely dissipate into the earth, preventing electric shocks, fires, and equipment damage.